Bending Parts Manufacturing Maintenance Sheet Metal CNC

Product Description

Bending Parts Manufacturing Maintenance Sheet Metal CNC

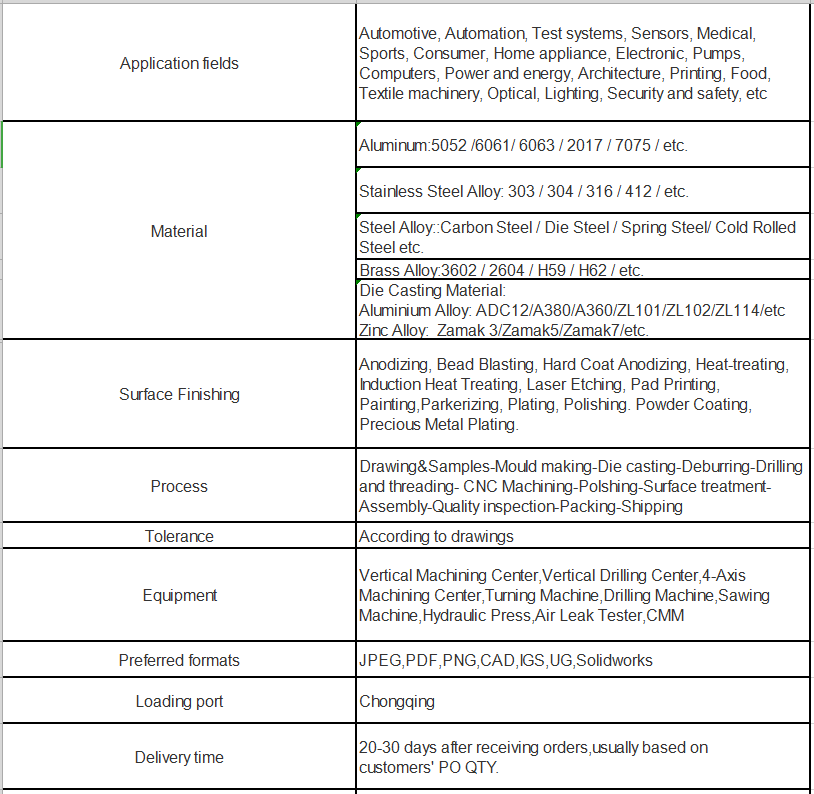

CNC bending services. Steel, stainless steel, alloy steel, aluminum, beryllium, brass and others Materials worked with. Products such as cans, covers, frames, shells, sanitary, angles and panels available. Cutting, forming, rolling, punching, stamping and other capabilities available. ISO 9001:2015 certified CNC multi axis tube bending & fabricating services from prototype to production volume. Fabricating services include bending, punching, laser cutting, welding (manual & robotic) & CNC machining. In-house bend die tooling, standard bend radii from tight mandrel bends to large sweeping roll bends, close tolerances, long & short runs, bending of uncoated & coated materials. 3/8 in. - 10 in. diameter tube capacity.

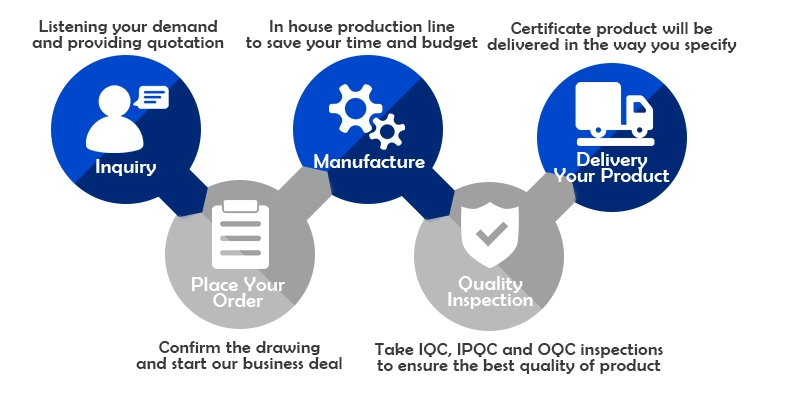

Business process

Related products

Product details

Company Information

Certification

Customers` visiting

Packaging &shipping

FAQ

1.What`s your warranty terms?

We will supply a replacement for parts that prove to be defective for a period of 18 months, starting on the machine`s bill of lading date.

2.what are our machining equipment?

The company owns more than seventy CNC machines including 8 sets 4-Axis CNC machining center.

3.Who are our mian customers?

BMW,ERICSSON,CHANA,ISUZU,LONCIN.

4.About our processing technology.

We will provide Die casting ,cnc machining,prototype parts.

Please kindly send us 2D&3D files for quote.

Product Categories : Sheet Metal Forming > Cnc Bending Stainless Steel